Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

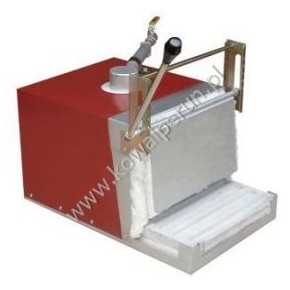

The MH500XL furnace for heat treatment of tool steels is a version of the MH 500 furnace with greater power and 3-phase power supply. Compared to the MH 500 furnace, it also has a higher and wider working chamber. The hardening furnace has a controller for setting the desired temperature, a thermoelectric sensor with a measurement error of +/- 0.4%, a safety switch activated after opening the furnace door and a fan cooling the housing. The floor of the furnace is made of fireproof bricks.

Type | MH500XL |

Chamber dimension (depth x width x height ) | 500x250x175 [mm] |

External dimentions (without door) (depth xwidth xheight ) | 650x500x530 [mm] |

Weight | 60 [kg] |

Controller | basic |

Power consumption | 4000W (17A) |

Power Supply | 400V (3f) |

Heating time to 1000OC | > 40 min. |

Max temperature | 1200OC |

Gas forge ITG1

Professional gas furnaces designed for companies and professionals in blacksmithing.

Gas forge ITG4

ITG4 furnace is equipped with four burners. Each burner have an independent valve to adjust the gas flow.

Gas forge C0-25

Forge C0- 25 is equipped with two burners...

Gas forge VKP 3

A one-burner forge indispensable for medium blacksmith workshops.The gas consumption amounts only 1 kg per hour at a constant operating temperature of 1250 ºC...

Gas forge VKP 5

A two -burner forge for medium and large blacksmith workshops. Ideal for heating a large amount of charge, especially in mass production...

Gas forge VKP 6

A four-burner forge for medium and large blacksmith workshops. Ideal for heating up a large amount of charge, particulary in mass production...