Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

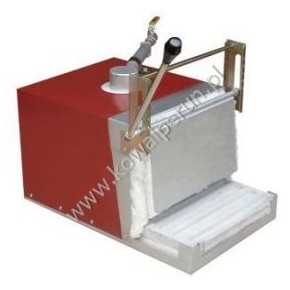

Professional gas furnaces designed for companies and professionals in blacksmithing. ITG1 furnace can be equipped with one or three burners. Each burner have an independent valve to adjust the gas flow.

All furnaces can be powered by LPG (both propane and propane-butane). You can also get them cusom-made powered by natural gas. The working chamber is made of Ceramic Fiber Boards which provide excellent thermal insulation. It results in a low gas consumption together with high temperatures inside the furnace.

We can add some extra equipment to the furnace such as a digital thermometer showing the temperature inside the chamber, and a furnace base.

See the table for more technical details.

Type of forge | ITG-1 |

Type of gas | Propane, Propane – Butane |

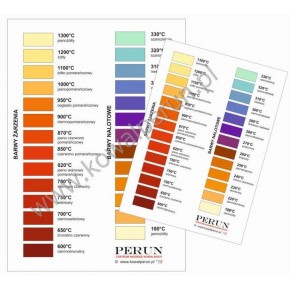

Operating temperature max | 1200 °C |

Weight | 25 kg |

Type of refractory lining | Ceramic Fiber Board |

Width of chamber | 280 [mm] |

Depth of chamber | 210 [mm] |

Height of chamber | 100 [mm] |

Gas consumption | 1,5 kg/h |

Gas forge ITG4

ITG4 furnace is equipped with four burners. Each burner have an independent valve to adjust the gas flow.

Gas forge VKP2

A one-burner forge perfect for medium blacksmith workshops. Economical and lightweight, with gas consumption of 1 kg per hour ...

Gas forge VKP 3

A one-burner forge indispensable for medium blacksmith workshops.The gas consumption amounts only 1 kg per hour at a constant operating temperature of 1250 ºC...

Reducer

Reducer: propane-butane...

Customers who bought this product also bought:

A hose 10 with ends

A hose 10 with appropriate ends, length: 1,5 ; 2; 2,5; 3; 4; 5 [m]

Universal tongs

Universal tongs 75x350, 85x400 mm

Flat bars tongs

Flat bars tongs

Conventional anvils with two horn type A

Cast steel anvils with two horns, weight 25 – 100kg.

Heading tools - strips with round holes

Heading tools - strips 15 [mm] thick

other products in the same category:

Gas forge ITG4

ITG4 furnace is equipped with four burners. Each burner have an independent valve to adjust the gas flow.

Gas forge ITG1

Professional gas furnaces designed for companies and professionals in blacksmithing.