Product successfully added to your shopping cart

Quantity

Total

There are 0 items in your cart. There is 1 item in your cart.

Total products (tax incl.)

Total shipping (tax incl.) To be determined

Total (tax incl.)

More info

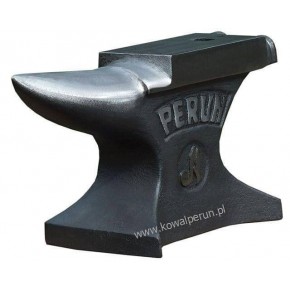

The body of the anvil is milled from the bottom, so that it firmly adheres to the base, and this largely reduces the noise generated during forging.

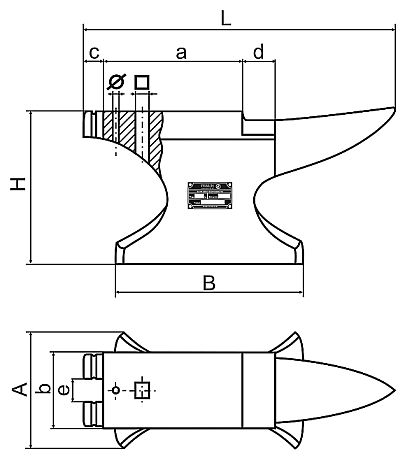

Technical data

See the table for more technical details.

| Farrier anvils PERUN | |||||||||||

| Weight | L | A | B | H | a | b | c | d | e | Ø | |

| 40 kg | 450 | 172 | 272 | 220 | 197 | 105 | 28 | 40 | 30 | 10 | 22 |

See also

Blacksmith trunk PERUN - anvil 25-50 kg

Blacksmith trunk for anvils weigth 25-50 kg...

Customers who bought this product also bought:

Blacksmith trunk PERUN - anvil 25-50 kg

Blacksmith trunk for anvils weigth 25-50 kg...